Client Portal

Client Portal

Access support, software, product info and more

Access support, software, product info and more

Client Portal

We’re keen for you to get the most from your Emesent products. Visit one of the categories below to download software updates and product information, submit support tickets, and sign up for training.

Start mapping the inaccessible…

Get in touch with our team of experts

Frequently Asked Questions

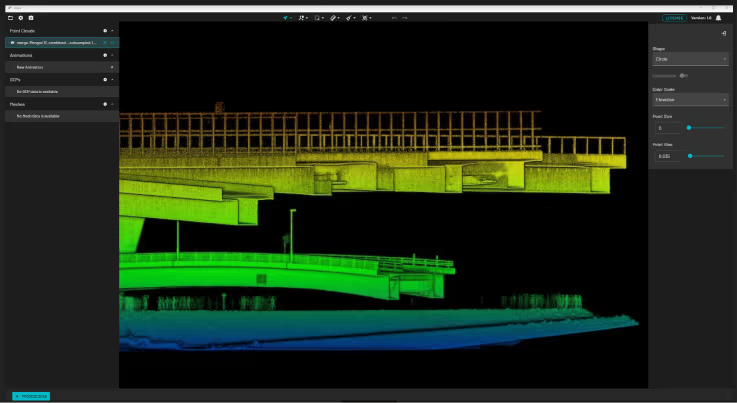

The output provided is a .Laz point cloud with point to mesh distance attributes and a .Ply mesh of the reference scan. Change is determined relative to within the drive, easily differentiating convergence from divergence. Colour scales are used to visualize the distance between the two scans.

Emesent's solution delivers an analysis-ready heatmap of time displacement across an entire mine. This can then be easily combined with other geological and geotechnical information to determine the root cause analysis or why that change is occurring, such as lithology, structural interpretations, seismicity data, and numerical modelling results showing stress and plastic strain.

Currently, the primary method for monitoring change in underground mining is damage mapping, which involves annotating two-dimensional cross-sections of the mine to indicate areas of concern. Although this method allows for broad spatial coverage, it is inherently subjective and lacks precision. In contrast, tape or digital extensometers offer high measurement accuracy at discrete points. However, due to the heterogeneous nature of rock masses—whose properties can vary significantly across tunnels, drives, and cross-sections—these point measurements are not always representative of broader conditions. Advanced tools like total stations and fixed laser sensors provide high accuracy but are limited in spatial coverage.

Each of these traditional methods serves a purpose, yet they also come with trade-offs in terms of scale, frequency, and reliability. As a result, many underground mines struggle to monitor change effectively, potentially compromising both safety and profitability.

Moreover, SLAM can inform the targeted placement of extensometers by identifying zones of potential movement, thus enhancing the value of high-precision point measurements. While a total station may detect millimeter-level shifts in key infrastructure – such as a mine entrance – SLAM complements this by enabling broader environmental scans. Similarly, while a fixed laser sensor might track stability in a crusher chamber during stoping, SLAM extends coverage to adjacent areas. In this way, SLAM does not replace traditional tools but enhances them, supporting a more comprehensive, scalable, and proactive monitoring approach.

Applications

Emesent Aura supports Change Detection and Convergence Monitoring for the following:

-

Convergence monitoring (gross/net displacement)

-

Convergence monitoring (rate)

-

Discontinuity mobilization (shear zones, faults, large-scale structure)

-

Brow damage after firing or mucking

-

Forensically analyzing rock bursting and seismic damag

-

Depth of damage

-

Ground support performance and residual capacity

-

Interactions between adjacent and overlying levels

-

Mine scale instability recognition

-

Tracking rehabilitation

Why use

Hovermap?

A Great Place To Work

We’re proud of the community we’ve built and work hard to foster a culture of trust, fairness, respect, and camaraderie. Our Great Place To Work Certification is a testament to our commitment to living Emesent’s mission, vision, and values.

Unique versatility

The plug and play design and quick-release mechanism allow easy switching between modes. Use Hovermap as a handheld scanner; attached to a drone, vehicle, or pole; lowered in a cage; or mounted to a backpack to easily collect data anywhere. The compact, lightweight design makes it easy to carry and provides longer flight time.

Accurate, adaptable data

The accurate and dense point clouds captured by Hovermap can easily be processed into necessary project deliverables, including CAD and 3D BIM models, using industry standard tools, such as PointCab, PointFuse, or Revit/AutoCAD.

PointCab Origins integration

This integration enables PointCab Origins to automatically detect a Hovermap scan and selects the project settings for the best results, resulting in clear images with more accurate vectorization. It will streamline the point cloud to model workflow, saving users time.